Successful Lime Plastering over Earthen Surfaces

In this blog, we're taking a deep dive into a topic central to natural building - lime plastering over earth surfaces. Drawing from my 20+ years of professional experience in natural building, and responding to repeated accounts of lime plaster failures over earthen substrates, I present what I have found is essential for success.

Key Takeaways:

- Historical Significance: Lime plastering over earth surfaces is a traditional practice with a rich history. Its longevity and prevalence in historical structures highlight its effectiveness and durability.

- Learning from Historical and Contemporary Practices: Analyzing both successes and failures in historical and modern lime plastering projects is invaluable for understanding best practices and avoiding common pitfalls.

- Material Properties: Understanding the distinct properties of earth and lime plasters is crucial. Earth plasters are ideal for interior use, while lime plasters are preferred for exteriors because of their durability and water resistance.

- Technique and Craftsmanship: Successful lime plastering over earth surfaces relies heavily on skilled craftsmanship, effective surface preparation, and careful detailing. It's a blend of art and science, requiring detailed knowledge of the materials and their interaction.

- Environmental Factors: The lime plastering process is sensitive to environmental conditions like humidity and temperature, making adaptability and understanding of these factors essential for successful application.

- Aftercare: Understanding the curing process and maintenance needs will keep your plaster in top condition.

- Appropriate Education: Training is vital for mastering lime plastering over earth surfaces. It encompasses both theoretical knowledge and practical skills.

The Enduring Legacy of Lime Plastering

Lime plastering over earth surfaces is a technique as ancient as it is beautiful. It is a traditional practice with a very rich history across most continents and climates. The longevity and prevalence of lime plasters in historical earthen structures highlight their effectiveness and durability.

Lime plasters create a unique aesthetic that blends seamlessly with natural elements, and offer a sustainable and compatible choice of surface finishes for earthen walls. For this reason, applying lime plasters to earthen substrates such as cob, adobe and rammed earth walls is a popular and appropriate choice, but it requires a nuanced understanding and meticulous execution. The points shared in this blog can be central to its success or failure.

Earth vs Lime as a Plaster Binder

In natural building, two primary materials are used as binders in plastering: earth and lime. Earth plasters are known for their softer texture and earthy tones. They are primarily suitable for interior applications since they are not water durable because they do not undergo a chemical set. Clay binder offers a range of other advantages, such as humidity regulation and total breathability.

Lime plasters, conversely, are valued for their chemical curing process, resulting in a harder finish that becomes even stronger over time. This makes them ideal for exterior applications, particularly due to their water-resistant properties. They often are also used in interior situations, which is a less critical scenario.

Lime plaster is very compatible with earthen walls, because it is breathable and flexible. However, its use over earth surfaces is a subject of much debate due to instances of failure, which often result from improper application rather than inherent incompatibility.

Understanding Lime Plaster Components

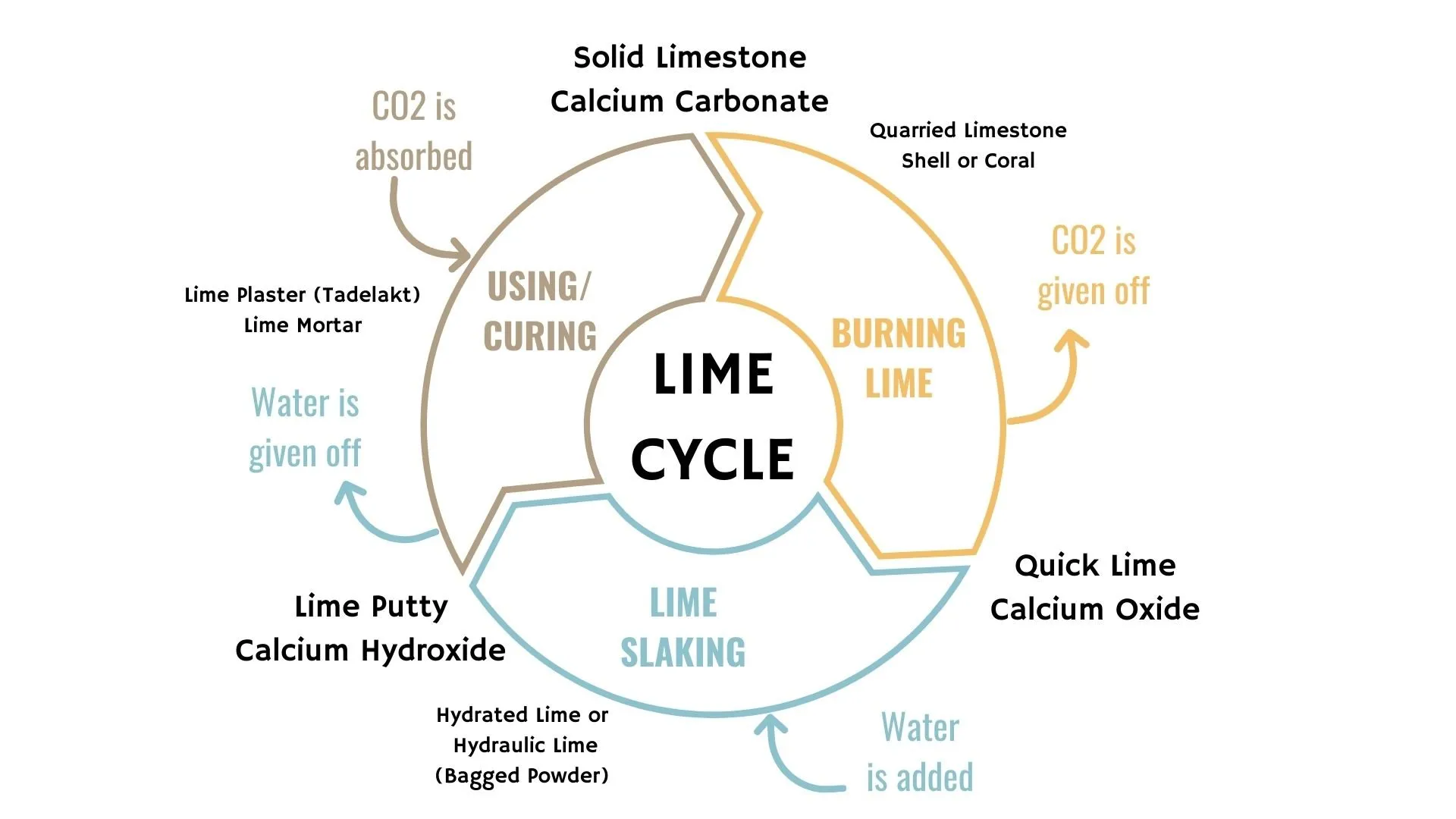

At its core, lime plaster is a simple mixture, but its components are critical to its performance. The main ingredient is lime itself, which is derived from limestone that's been burnt and slaked with water. When mixed with an aggregate like sand, it creates a pliable paste that can be spread over surfaces. As it dries and reacts with carbon dioxide in the air, it turns back into limestone, hardening to form a protective layer.

The type of lime and the quality of the sand are pivotal. Hydrated lime, also known as Type S, is commonly used for its workability and high strength. The sand should be well-graded and free of impurities to ensure a strong bond and a smooth finish. Sometimes, fibers like straw or hair are added to the mix to prevent cracking and improve tensile strength.

The Challenges of Lime Plastering Over Earth

Plaster Bond

One of the main challenges in lime plastering over earth surfaces is achieving a strong bond. Lime and earth do not bond chemically. The adhesion is primarily mechanical, relying on the texture and preparation of the earth surface. This is where skilled craftsmanship and understanding of the materials plays a crucial role.

Plaster Delamination

Furthermore, the lime plaster coat is not completely impervious to moisture in an exposed exterior situation. While it doesn’t erode from rain, moisture can still be wicked through and eventually reach the earthen substrate. If this happens often and excessively, the earthen surface below the lime plaster can swell and shrink in wet-dry cycles, which eventually will lead to delamination.

Detailed Plaster Process and Techniques

The process of applying lime plaster over earth surfaces involves several critical steps:

Surface Preparation

The plaster must be able to bond with the substrate, and the substrate should be stable enough to support the plaster. Ensuring the earth surface is stable, free of dust, and has the right texture and roughness is essential for good mechanical grip. Since lime plaster doesn’t bond with the earthen substrate chemically, it is essential to create a surface profile that the lime plaster can adhere to effectively.

Choosing the Right Mix

The composition of the lime plaster mix is vital. It must be suited to the specific type of earth surface it's being applied to, taking into account factors like the thickness of the plaster coat, the type of sand, and curing conditions. It is advisable to do tests to finetune plaster components and ratios.

Application Method

The technique of application is a craft in itself. It requires appropriate tools and applying the right amount of pressure, ensuring even coverage. It is advisable to work in several coats, depending on how uneven the substrate is. It is also important to understand how the plaster behaves as it sets, and to ensure the set doesn’t happen too fast.

Total Plaster Thickness

The plaster thickness is one of the most important factors when executing successful lime plasters over earthen substrates. Lime plasters are not impervious to moisture ingression, they are just water-durable. If the surface of the plaster is left untreated and is exposed to prolonged periods of rain, moisture will wick through to the earthen substrate. This could lead to wet-dry cycling and swelling and shrinking of the earthen material, which eventually could lead to delamination.

Applying the lime plaster thick enough will reduce the risk of moisture penetrating all the way to the substrate. A minimum thickness of 20mm, applied in 2-3 coats, is recommended. It is also important to ensure the plaster is not sealed with any finishes that could compromise breathability, so that it can dry out after rain events.

Environmental Factors

Lime plastering is sensitive to environmental conditions, such as humidity and temperature. Understanding how these factors impact the setting and curing of the plaster is crucial for a successful application. It is advisable not to work in conditions that could lead to too fast or slow curing. Temperatures between 5-25 degrees Celsius are best, and it is recommended to install shade and protection for the plaster while it cures. Fresh plaster should be misted regularly for a duration of time, to further aid with curing.

Additional Surface Treatments

In exposed exterior situations, further surface treatments of the lime plaster are also recommended, and will greatly increase the durability of the plaster, and reduce the risk of failure. Traditionally, this would have been done with lime wash, which was regularly renewed. In modern applications, it might not be economic to work with limewash and the application of a breathable silicate paint is best practice. Silicate paint greatly reduces moisture penetration into the lime plaster, while keeping the surface breathable.

Further reading on the comparison of lime wash and silicate paint.

Learning from Failures

In our discussions at the Earth Building Academy, we often analyze cases where lime plastering over earth surfaces has failed. These failures are not indictments of the practice itself but rather valuable learning opportunities. They highlight the importance of understanding the materials, the environmental conditions, and the application techniques.

The Artisan's Touch in Lime Plastering

Lime plastering transcends mere construction; it's an art that marries scientific understanding with artisanal skill. This craftsmanship, honed through years of experience, is what we impart to our students in the Natural Building Course.

Training for Excellence

Our course offers extensive knowledge in lime plastering, covering historical context, material properties, and practical application techniques. Our aim is to equip participants with the expertise needed to execute this technique successfully in their projects.

Video Learning for Enhanced Understanding

To complement this written content, I invite you to watch a video from a recent presentation I gave. It offers visual and practical insights into lime plastering over earth surfaces, enhancing your understanding of this traditional technique.

The Fusion of Tradition and Modernity in Lime Plastering

Lime plastering over earth surfaces is not just about preserving traditional methods; it's about adapting them to contemporary contexts. This fusion of old and new makes the technique both a preservation of heritage and a viable option for current natural building projects.

The Importance of Contextual Application

Understanding the specific context in which lime plaster is applied is crucial. Factors like local climate, the specific type of earth surface, and the intended use of the building all play a role in determining the most effective application strategy.

The Future of Lime Plastering in Natural Building

As we look to the future, lime plastering continues to hold a significant place in sustainable building practices. Its ability to be both environmentally friendly and structurally sound positions it as a key technique in the evolution of natural building.

Conclusion

The art of lime plastering over earth surfaces is a testament to the enduring nature of traditional building techniques and their relevance today. As we continue to explore, teach, and apply this method, we are committed to preserving these skills for future generations of builders. Join us on this journey of discovery and mastery in natural building, where tradition meets innovation.

FAQs

Can Lime Plaster Be Applied over Any Type of Earth Surface?

While lime plaster is versatile, it's not a one-size-fits-all solution. It adheres best to surfaces that are stable and have a certain level of moisture durability. Earthen surfaces like adobe, cob, rammed earth and LEM are ideal. We do not recommend to apply lime plaster over a base coat of earthen plaster, as this type of substrate typically has a high ratio of sand added already. Earth plaster substrates are not very moisture resistant while the lime plaster is curing, or if there ever is moisture ingression through the lime plaster. There is an increased risk of failure through delamination.

How Does Weather Affect Lime Plastering?

Weather can be a lime plasterer's best friend or worst enemy. Ideal conditions are humid and mild. If it's too wet, the plaster won't set properly or might get damaged by rain, and if it's too dry, it can crack and cure too quickly. Wind can also be a problem as it can cause the plaster to dry too fast, leading to a cracking and a weak finish. Freezing temperatures can lead to complete plaster failures. Therefore, timing your plastering project with the weather forecast is crucial. And if the weather isn't cooperating, creating a protective environment using tarps or temporary shelters can help.

How Long Does It Take for Lime Plaster to Fully Cure?

The curing time for lime plaster can vary significantly. It depends on the thickness of the plaster, the ambient temperature and humidity, and the composition of the mix. A general rule of thumb is that it takes about a week per millimeter of thickness to cure fully at room temperature. But it's not uncommon for thick coats or plasters in cooler climates to take several months to carbonate completely. Patience is essential, as rushing this process can lead to a poor-quality finish. It is advisable to wait until the plaster is well-cured before applying silicate paint.

What Are the Main Benefits of Lime Plaster Over Other Plasters?

Lime plaster stands out for several reasons. Firstly, it is the only exterior plaster that has a chemical set that is compatible with earthen walls. Cement plasters are not compatible with earthen materials because they trap moisture and are too brittle. The production of lime plaster emits less carbon dioxide compared to cement-based plasters. It's also highly breathable, which means it can regulate indoor humidity and prevent mold growth. Durability is another plus; a well-applied lime plaster can last for decades, even centuries, with minimal maintenance. Lastly, it has a unique aesthetic appeal, providing many options for textures and finishes that are hard to replicate with other materials.

Can Lime Plaster Be Colored or Textured During Application?

Yes, lime plaster can be both colored and textured, which is part of its charm. Natural pigments can be added to the mix before application to achieve a wide range of colors. As for texture, it's all in the technique and tools used. You can create anything from a smooth, polished surface to a rustic, rough finish. Experimenting with different trowels, brushes, and even your hands can yield a variety of textures that add character to your walls. Exterior lime plasters are often finished with silicate paints, which mimic the beautiful matte finish of a lime wash, but are much more durable.